Unyango lwesiseko sesiza

1. Ngaphambi kokubeka i-geomembrane ye-HDPE, isiseko sokubeka siya kuhlolwa ngokubanzi kunye namasebe afanelekileyo.Isiseko sokubeka siya kuba siqinile kwaye sicaba.Akusayi kubakho zingcambu zemithi, ingqushu, amatye, amasuntswana ekhonkrithi, iintloko zokuqinisa, iitshiphusi zeglasi kunye nolunye ubutyobo olunokonakalisa i-geomembrane ngaphakathi kubunzulu obuthe nkqo obuyi-25 mm.Sebenzisa i-wheel compactor ukuhlanganisa ukususa iimpawu zemoto, iinyawo kunye namaqhuma aphantsi.Ukongeza, amaqhuqhuva asemhlabeni angaphezu kwe-12mm nawo aya kutyunyuzwa okanye ahlanganiswe.

2. Xa i-HDPE geomembrane ibekwe kwi-backfill, ukubumbana kokuzaliswa ngasemva akuyi kuba ngaphantsi kwe-95%.

3. Isiseko sesiza siya kukhululeka ekubhobhozeni kwamanzi, udaka, ukudada, intsalela yendalo kunye nezinto ezinobungozi ezinokudala ungcoliseko lokusingqongileyo.Ikona yesiseko iya kuba mpuluswa.Ngokuqhelekileyo, i-arc radius yayo ayiyi kuba ngaphantsi kwe-500 mm.

Iimfuno zobugcisa zofakelo lwe-HDPE geomembrane.

1. Ukubekwa kunye nokuwelda kwe-HDPE geomembrane kufuneka kuqhutywe kwimozulu apho ubushushu bungaphezu kwe-5 ℃ kwaye amandla omoya angaphantsi kweBanga lesi-4 ngaphandle kwemvula okanye ikhephu.

2. Inkqubo yolwakhiwo lwe-HDPE geomembrane iya kuqhutywa ngolu hlobo lulandelayo: ukwandlalwa kwe-geomembrane → ukuwelda iijoyinti zokuwelda → ukuwelda → uhlolo lwendawo → ukulungisa → ukuphinda kuhlolwe → ukuzaliswa ngasemva.

3. Ububanzi obugqithisiweyo bamajoyina phakathi kweembrane abuyi kuba ngaphantsi kwe-80mm.Ngokuqhelekileyo, ulwalathiso lolungiselelo oludibeneyo luya kulingana nomgca we-slope esiphezulu, oko kukuthi, kuya kulungiswa kunye nolwalathiso lwe-slope.

4. Ngexesha lokubekwa kwe-HDPE geomembrane, imibimbi eyenziweyo iya kuphetshwa kangangoko kunokwenzeka.Xa ubeka i-HDPE i-geomembrane, i-deformation yokwandisa okubangelwa utshintsho lweqondo lokushisa kuya kugcinwa ngokuhambelana noluhlu lokutshintsha kweqondo lokushisa kunye neemfuno zokusebenza ze-HDPE geomembrane.Ukongeza, isixa sokwandiswa kwe-geomembrane iya kugcinwa ngokwendawo yesiza kunye nokubekwa kwe-geomembrane ukulungelelanisa ukuhlaliswa okungalinganiyo kwesiseko.

5. Emva kokuba i-HDPE geomembrane ibekwe, ukuhamba kwi-membrane surface kunye nezixhobo zokuphatha ziya kuncitshiswa.Izinto ezinokubangela ingozi kwi-HDPE geomembrane aziyi kufakwa kwi-geomembrane okanye zithwalwe kwi-geomembrane ukuphepha umonakalo owenziwe ngengozi kwi-membrane ye-HDPE.

6. Bonke abasebenzi abakwisiza sokwakha ifilimu ye-HDPE abayi kutshaya, banxibe izihlangu ezinezikhonkwane okanye izihlangu eziqinileyo ezine-heeled eziqinileyo ukuze bahambe kumphezulu wefilimu, okanye babandakanyeke kuwo nawuphi na umsebenzi ongonakalisa ifilimu engagxumekiyo.

7. Emva kokuba i-geomembrane ye-HDPE ibekwe kwaye ngaphambi kokuba ukhuselo lugqunywe, ingxowa yesanti ye-20-40Kg iya kufakwa kwikona ye-membrane rhoqo nge-2-5m ukukhusela i-geomembrane ekubeni ivuthelwe ngumoya.

8. I-HDPE geomembrane iya kuba yendalo kwaye isondele kumaleko axhasayo, kwaye ayiyi kusongwa okanye inqunyanyiswe emoyeni.

9. Xa i-geomembrane yakhiwe ngamacandelo, umgca ophezulu uya kugqunywa ngexesha emva kokubeka, kwaye ixesha elibonakalisiweyo emoyeni aliyi kudlula iintsuku ezingama-30.

I-ankile ye-HDPE geomembrane iya kuqhutywa ngokoyilo.Kwiindawo ezinomhlaba onzima kwiprojekthi, iyunithi yokwakha iya kuphakamisa ezinye iindlela zokubambelela, eziza kwenziwa emva kokufumana imvume yeyunithi yoyilo kunye neyunithi yokulawula.

Iimfuno ze-HDPE geomembrane welding:

1. Umphezulu odityanisiweyo we-HDPE geomembrane weld awuyi kuba nobumdaka, isanti, amanzi (kubandakanywa nombethe) kunye nobunye ukungcola okuchaphazela umgangatho we-welding, kwaye iya kucocwa ngexesha le-welding.

2. Ekuqaleni kwe-welding yonke imihla (ekuseni nangemva kwesidlo sasemini), uvavanyo lwe-welding kufuneka luqhutywe kwindawo yokuqala, kwaye i-welding esemthethweni inokuqhutywa kuphela emva kokuba ifanelekile.

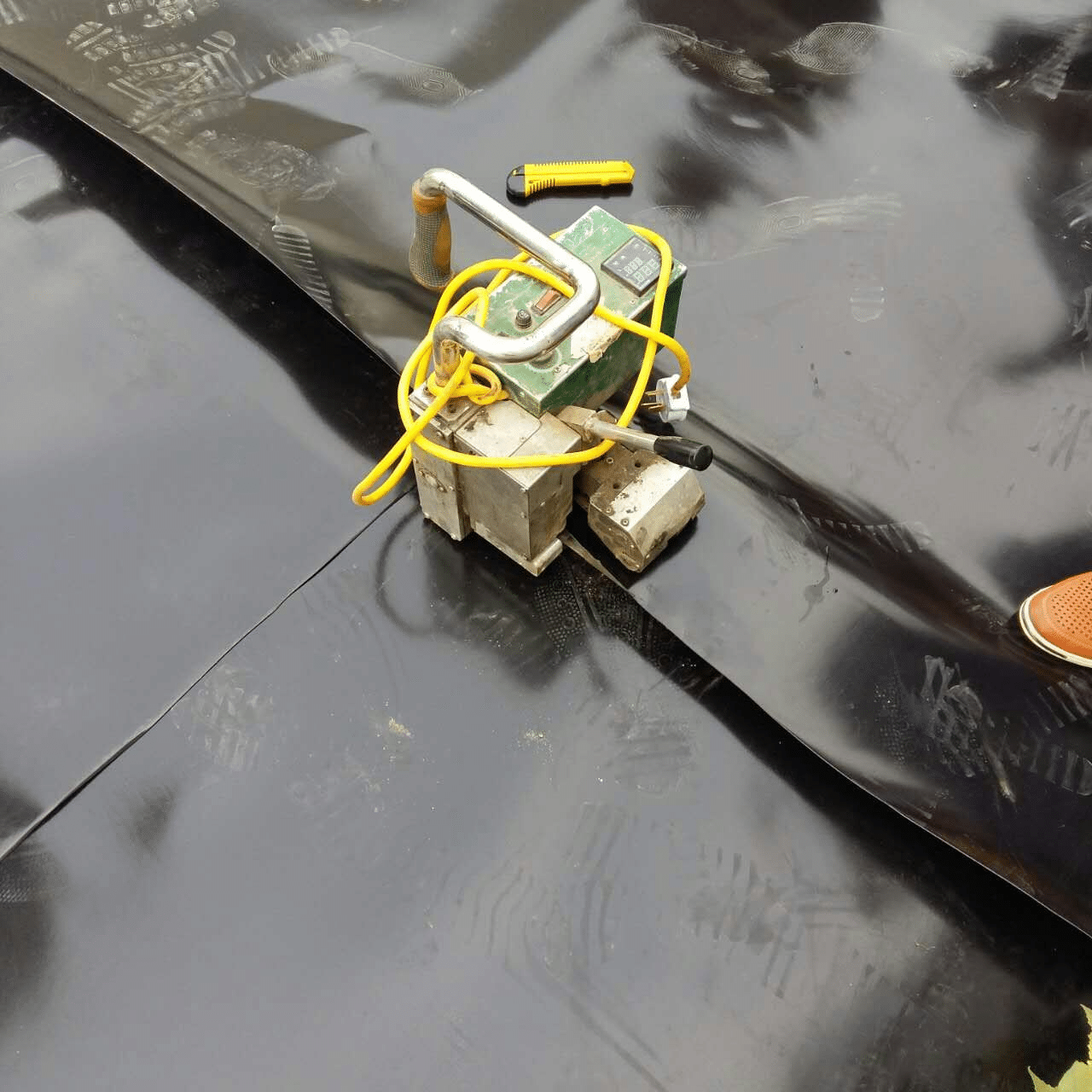

3. I-geomembrane ye-HDPE kufuneka ifakwe nge-double track hot-melt welding machine, kunye ne-extrusion welding okanye i-hot-air gun welding kufuneka isetyenziswe kuphela kwiindawo apho ukulungiswa, ukugubungela okanye umshini wokushisa otshisayo awukwazi ukufikelela.

4. Ngexesha lokwakha, ukushisa okusebenzayo kunye nesantya somatshini we-welding kuya kulungelelaniswa kwaye kulawulwe nangaliphi na ixesha ngokuhambelana nokushisa kunye nezinto eziphathekayo.

Ifilimu ye-5.HDPE kwi-weld iya kuxutywa ngokupheleleyo, kwaye ayiyi kuba ne-welding yobuxoki, i-welding elahlekileyo okanye i-welding engaphezulu.Imigangatho emibini edibeneyo ye-HDPE geomembrane kufuneka ifakwe i-flat and gentle.

Ulawulo lwekhwalithi ye-weld

Ngenkqubela phambili yokwakha, kuyafuneka ukuba kuhlolwe umgangatho we-welding yefilimu ye-HDPE ngexesha, kunye nokulungisa i-welding nge-hot air gun okanye i-plastic welding gun nangaliphi na ixesha ngenxa ye-welding elahlekileyo kunye ne-welding ephosakeleyo.Iindlela ezikhethekileyo zezi zilandelayo:

1.Uhlolo lwenziwa ngamanyathelo amathathu, oko kukuthi ukuhlolwa okubonakalayo, ukuhlolwa kokunyuka kwamaxabiso kunye novavanyo lomonakalo.

2. Ukuhlolwa okubonakalayo: khangela ukuba i-welds ezimbini zisicaba, zicacile, azishwabanisi, zicacile, zikhululekile, i-bubble, indawo yokuvuza, indawo yokunyibilika okanye i-weld bead.

Ukuhlolwa okubonakalayo ngokukodwa kukuhlola ngononophelo inkangeleko ye-geomembrane ebekiweyo, umgangatho we-weld, i-welding ye-T-shaped, i-substrate debris, njl njl. Bonke abasebenzi bokwakha baya kuwenza lo msebenzi kuzo zonke iinkqubo zokwakha.

3. Ukongeza ekuhlolweni okubonakalayo, ukuhlolwa kwe-vacuum kuya kwamkelwa ukwenzela ukuqina kwazo zonke i-welds, kwaye ukuzihlola ngokwakho kuya kuqiniswa kwiindawo ezingenakuhlolwa nge-vacuum.

4. Amandla okunyuka kwamaxabiso afunyenwe yi-inflation pressure yi-0.25Mpa, kwaye akukho kuvuza komoya kwimizuzu emi-2.Ukuqwalasela ukuba izinto ezidibeneyo zithambile kwaye zilula ukukhubazeka, ukuhla koxinzelelo oluvumelekileyo yi-20%

5. Xa uqhuba uvavanyo lwe-tensile kwisampulu ethathwe kwi-double rail weld, umgangatho kukuba i-weld ayikrazulwa kodwa umama ukrazulwe kwaye wonakaliswe ngexesha lovavanyo lwe-peel kunye ne-shear.Ngeli xesha, i-welding ifanelekile.Ukuba isampuli ayifanelekanga, isiqwenga sesibini siya kuthathwa kwi-weld yokuqala.Ukuba iziqwenga ezintathu azifanelekanga, yonke i-weld iya kuphinda isetyenzwe.

6. Iisampulu eziphumelele uvavanyo ziya kungeniswa kuMnikazi, iKontraka Jikelele kunye neeyunithi ezifanelekileyo ukuze zifakwe.

7. Iziphene ezifunyenwe ekuhloleni okubonakalayo, ukufumanisa ukunyuka kwamaxabiso kunye nokuvavanya umonakalo kuya kulungiswa ngexesha.Ezo zingenako ukulungiswa ngokukhawuleza ziya kumakishwa ukuthintela ukushiywa ngexesha lokulungiswa.

8. Ekuhlolweni kwenkangeleko, xa kukho iziphene ezinje ngemingxuma kumphezulu wenwebu kunye newelding elahlekileyo, ukuwelda okungalunganga kunye nomonakalo ngexesha le-welding, isiseko esitsha sesinyithi siya kusetyenziselwa ukulungisa kwangethuba, kwaye icala ngalinye lesiva elilungisiweyo liya kudlula i-welding. inxalenye eyonakaliswe ngu 10-20cm.Yenza iirekhodi.

9. Ukulungiswa kwe-weld, ukuhlolwa okubonakalayo okucacileyo kuya kwenziwa ngokubanzi, kwaye ukukhululwa kuya kwenziwa emva kokuba ukulungiswa kuqinisekiswe ukuba kunokwethenjelwa.

Ixesha lokuposa: Dec-14-2022